PFAS are a group of recalcitrant substances, implemented in a broad range of consumer products. Concern for their effects on the environment were raised when it was discovered that they are mostly resistant to biodegradation, accumulate in the ecosystem and are toxic to human health. [1] Humans can come into contact with PFAS through traces mainly in drinking water but also in food such as fish, meat and vegetables. Due to the broad range of different PFAS molecules, PFAS presents a challenge for environmental remediation. [2]

As HMVT we receive a lot of PFAS related (ground)water treatment requests and we scan the world constantly on new developments in treating options. An interesting, creative method would be to use the power of plants and to treat the water in Constructed Wetlands. Such solutions would have the benefit of low energy consumption, maintenance costs and low carbon footprint. Such method could be employed when dealing with lower concentrations of PFAS, for instance to control groundwater or leachate plumes. The treatment is based on the adsorption of PFAS onto the constructed wetland filter bed, with subsequent transformation by the microbiome and up-take by the wetland plants, which can be harvested and incinerated. Together with Lagua from Sweden we have performed simple bench-scale experiments regarding this treatment method, with promising results.

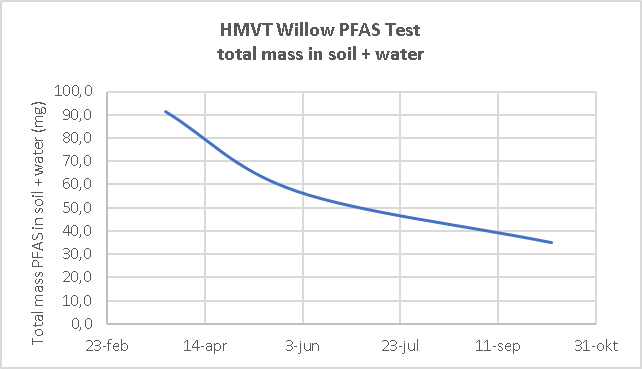

The set-up showed a total PFAS removal of 61% over the growth period of the willows (figure 2).

In this experiment, a bench-scale set-up had soil containing PFAS from a fire-fighters practice site (see figure 1). In this set-up, willows were planted into the soil to absorb the PFAS. The soil on which the willows grew started out with a PFOS concentration of nearly 2 mg/kg, and the water with 1.5 mg/l.

In the plants, significant PFAS levels were detected, in total approximately 620 µg/kg willow. These levels are comparable to those seen in literature[1]. The willows grew on a surface of approximately 0.25 m2, and yielded 2.2 kg of plant material.

When extrapolating the data from the willows, a total amount of PFAS can be treated of 9,40 mg/m2 or 94 g/ha in a span of 1 year. Depending on the concentration of the PFAS in the to-be-treated stream and the size of the plume, constructed wetlands planted with willows could be a viable option to treat this.

We are interested to test this further with partners or problem owners. To see whether this method is viable to treat PFAS, it would be interesting to perform more experiments with this technique and see if it is also feasible in a pilot-scale environment.

More info? Contact us via info@hmvt.nl

[1] Stoiber, T., Evans, S., & Naidenko, O. V. (2020). Disposal of products and materials containing per-and polyfluoroalkyl substances (PFAS): A cyclical problem. Chemosphere, 260, 127659.

[2] Concawe – Review of water treatment systems for PFAS removal report no. 14/20.

[3] Shahsavari, E., Rouch, D., Khudur, L. S., Thomas, D., Aburto-Medina, A., & Ball, A. S. (2021). Challenges and current status of the biological treatment of PFAS-contaminated soils. Frontiers in Bioengineering and Biotechnology, 1493.